Curtis

Curtis Compressors

Rotary Screw Compressors

RS Series 15-300 HP

The rigid base includes built-in forklift slots to reduce the risk of damage. Add in the meticulous selection of components, such as premium efficiency motors (up to 200 HP), generously sized coolers and airends, and it’s easy to see why RS Series compressors have earned a reputation for durability and performance.

- Superior durability handles even the most demanding applications

- High-efficiency separation and filtration for long life

- Open design offers easy access to all components — no need to remove panels or brackets

- Rugged and leak-free design

- Easy servicing for low cost of ownership

- Exclusive slow speed airend profile results in higher air delivery while reducing power consumption

- Proven control technology for power savings and pressure stability in all demand loads

- NEMA Premium Efficiency motors

- Low internal pressure drops increases efficiency

NX Series 4-260 kW

- Designed for quite operation

- Built to the highest levels of dependability and reliability

- Designed for low cost of ownership

- Ideal combination of variable speed drive, controller, and drivetrain

- Protects critical components from compressor-generated heat

- Intelligent component layout optimizes cooling air flow through the package and improves overall efficiency and reliability

- Extends component life and reduces downtime

NxHE Series Two – Stage

- Centrifugal cooling fan and compartmentalized package air flow make for extremely smooth and quiet operation

- Extra thick, laminated oil-proof sound insulation greatly reduces noise

- Protects critical components from compressor-generated heat

- Intelligent component layout optimizes cooling air flow through the package and improves overall efficiency and reliability

- Extends component life and reduces downtime

- Exclusive FS-Curtis air end utilizes precision cut rotor profiles to maximize efficiency.

- Premium efficiency TEFC (IP55, Class F) main motor protects against dust ingression and high operating temperatures, prolonging the life of the motor.

- Components are generously sized to reduce pressure drop throughout the package, increasing overall efficiency

Oil- Free Compressors

Eco Turbo

- ECO-Turbo 185-250kW Removable enclosure panels allow for easy access to all maintenance components

- Airend designed with horizontally split gearbox allowing for quick inspection of impellers and gears

- 100% oil-free, Class 0 (ISO 8573) compressed air

- 2-stage compression for greater energy efficiency

- Long service life

- Low maintenance costs

- Premium efficiency TEFC (IP55) main motor

- Wear-free titanium impeller designed for long life and optimum efficiency

- Sound enclosure with removable panels protects compressor from harsh environments

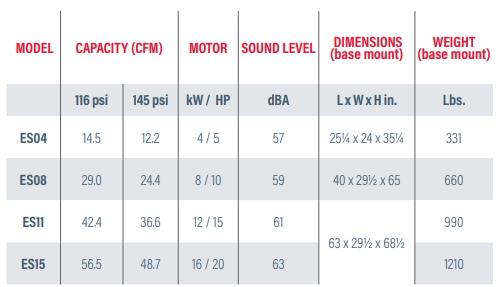

Eco Scroll

- Designed to be installed in applications where quiet setting is important

- Noise level between 57 and 63 dBA

- No inlet valve knocking noise

- Ultra low vibration (5mm/s or less)

- Powered by high efficient motor TEFC IE3

- Exclusive ECO-Series scroll airend

- Fixed and orbital scrolls are precisely meshed

- Centrifugal cooling fan keeps heat exchange efficient and quiet

- Check valves and safety relief valves in line to prevent back pressure to the airend

- 100% duty cycle

- Units are start/stop controlled

- Can be oversized without harm to scroll airend

- Lower carbon footprint with environmentally friendly ISO 8573-1 Class 0 Air

- Unit installation in workspace gives you reduced installation costs

- Promotes energy conservation by avoiding the use of oil

- Maintenance friendly

- Less moving parts results in higher reliability

- Small footprint, space saving modular design

- Easy to use electronic controller

Reciprocating Compressors

CT Series 5-10 HP

- Magnetic motor starter*

- Cast-iron 2-stage pump built to ISO 9001 standards

- Slow speed pump with V-belt drive

- Rugged NEMA motor with UL-approved electric design

- ASME air tank

- OSHA-approved totally enclosed metal belt guard

- UL-approved pressure switch

- Automatic start-stop control

- Metal intake filter/silencer

- Manual tank condensate drain valve

- Dial read-out pressure gauge

- Loadless starting

- ASME-approved safety valve

- ASME-approved discharge valve

- Factory oil filled

Piston & Oil- Less Compressor

OL Series 5-15 HP

- 100% dry crankcase provides oil-less compressed air for critical applications with zero oil carryover

- Over-sized fan and multiple inter-stage cooling pipes to maximize heat transfer for lower discharge temperature

- Environmentally friendly with no oil vapor generated by the compressor. Eliminates oil changes and oil disposal costs

- Protects downstream equipment and reduces maintenance cost

- Decreases costs and reduces system pressure loss due to reduction of air filtration equipment in the compressed air system

- Low speed pump for long-term reliability and efficiency

- 100% duty cycle for continuous operation

- Robust cast-iron crankcase, cylinder, and cylinder head for long-lasting performance

ML (Master Line) Series 5-30 HP

- Proprietary technology is an FS-Curtis exclusive

- Supplies pressurized oil internally to all bearings and critical wear surfaces through the rifle-drilled crankshaft and connecting rods

- Helps ensure maximum uptime and increase service life

- Industry-leading stainless-steel valve assemblies for increased airflow and reliability

- Oversized tapered main roller bearings to ensure long life

- Premium finned intercooler maximizes heat dissipation

- Metal intake filter/silencer is superior to plastic

- Heavy-duty stamped-steel belt guard

- Suction valve head unloaders for continuous running air compressors

- Some pumps claim 100% cast-iron yet still have aluminum cylinders, cylinder heads, connecting rods and crankshafts – not FS-Curtis

- Ductile cast-iron crankshaft and connecting rods are stronger, more corrosion-resistant and less likely to break

- Slow-turning pump increases pump life

- Rugged parts and construction for industrial performance

CA Series 5-15 HP

- Industrial-grade main roller bearings are precision fit for support of all rotating parts

- High-flow, heavy-duty stainless-steel valve system delivers more cfm per horsepower

- Robust intercooler increases compressor efficiency

- Metal intake filter/silencer is superior to plastic

- Heavy-duty stamped-steel belt guard

- Suction valve head unloaders for continuous running air compressors

- Choose between Kohler or Honda engines

- Tank mount or base mount configurations

- OSHA-approved totally enclosed metal belt guard

- ASME-approved air receiver

- 12V DC starter with alternator

- Engine idle control

Because FS Curtis offers so many replacement parts we do not list them here on this site.

Call or email us with your PART NUMBER or for assistance finding it.

Call Us:

(586) 558-9100

Business Hours

Mon-Fri 8am-5pm

24-Hour Emergency

Content, including images, displayed on this website is protected by copyright laws. Downloading, republication, retransmission or reproduction of content on this website is strictly prohibited. Terms of Use

| Privacy Policy