Hankison

Hankison Air Dryers and Filters

Air Dryers

Filters

Hankinson Air Dryers

RNP Series - Non-Cycling Refrigerated Air Dryer

Curtis/Hankinson combines reliability, cutting-edge design, and innovative packaging to supply the best air treatment package in a space saving unit. The air quality delivered from a CNC Series dryer will define the difference between moderate and superior results from your plant’s processes or systems.

Details

RNP Series non-cycling refrigerated air dryers are engineered to benefit you for a lifetime. Quality components and engineering excellence are bonded together to ensure you of a stable 38°F pressure dew point.

- 10-3,000 scfm

- Ensures 38°F dewpoint

- Four levels of controllers

RDS-1 Series - Cycling Refrigerated Air Dryer

The RDS-1 Series cycling refrigerated air dryers feature a load matching design which saves you money and reduces your costs. Featuring standard built-in air filtration and no-air-loss condensate drains ensures these dryers are a great choice for your compressed air drying needs.

Details

The RDS-1 Series refrigerated dryer automatically cycles the refrigeration compressor on and off in response to inlet load conditions. As the inlet air load is reduced, the refrigeration compressor cycles off, providing you with the ability to reduce energy and costs.

- 90 - 675 scfm

- Energy Saving

- ISO 8573.1 air quality built-in

RDS-2 Series - Digital Scroll Refrigerated Dryer

The energy saver RDS-2 Series digital scroll dryer is unlike any energy efficient compressed air dryer technology on the market.

Details

Challenges for energy efficiency and dew point stability are answered with a technological breakthrough in energy efficient refrigerated air dryer design in the RDS-2 Series. Curtis/Hankinson continues the tradition of providing energy saving solutions to help you increase profits and reduce power costs.

- 800-3,000 scfm

- Energy efficient, digital scroll technology

- 38°F dew point stability

CAF Series - Compressed Air Filter

Details

CAF Series filters maximize filtration efficiency through their two-stage, inside-to-outside air flow design.This innovative design ensures long element life while stainless steel inner and outer cores add structural integrity.

CAF Series filters provide your compressed air system with premium quality filtration against solid particles, condensed water droplets ad liquid oil and oil vapors.

Solid particles come from ambient air contaminants like dust and from rusted, oxidized pipework. These particles cause pneumatic equipment to malfunction, instrument and control failures, and contaminate end products.

Condensed water droplets come from the humidity in ambient air. This moisture will oxidize pipework and pneumatic equipment and also ruin paint finishes.

Liquid oil and oil vapors are introduced by compressor lubricants and by hydrocarbon vapors present in ambient air. Oil-free compressed air is particularly important in food and pharmaceutical processes.

- 20-21,250 scfm

- Six grades of filtration

- 300 psig maximum working pressure

CHA Series - High Temperature Air Compressor Filters

Effective at temperatures up to 450°F, the CHA Series filters provide superior filtration for high temperature applications. With cast aluminum end caps and welded carbon steel housings, you can count on the superior reliability of the CHA Series.

Details

The CHA Series removes solid particulates resulting from desiccant dust to 1 micron.

- 100-11,400 scfm

- 450°F maximum inlet temperature

- Effective two-stage filter element design

CME Series - Mist Eliminator

The CME Series mist eliminators are used to reduce energy costs and remove oil and water aerosols from compressed air systems. Incorporating superior installation flexibility and ability to increase the life of pneumatic equipment.

Details

Protecting products and processes from contamination, helping eliminate paint appearance and adhesion problems, and keeping pneumatic instruments operating are all benefits of using a CME mist eliminator.

- 125-3,000 scfm

- Low pressure drop

- Optional automatic condensate drain

Parker Finite Airtek Filtration

Parker Finite Air Dryers and Filters

Air Dryers

Filters

Parker Finite Air Dryers

Finite's FDD Desiccant Dryer Series

Finite's FDD Desiccant Dryer Series is designed to remove water vapor and aersols at point-of-use for intermittent flows up to 60 SCFM. These dryers can reach dewpoints down to -40°F.

FMD Membrane Dryer Series

Finite's FMD Membrane Dryer Series is designed to remove water vapor and aersols at point-of-use for intermittent flows up to 40 SCFM with a +35°F dewpoint and 10 SCFM with a -40°F dewpoint.

- Designed for point-of-use applications

- Pressures to 150 PSIG

- No moving parts

- Drying efficiency down to -40°F pressure dewpoint

- Quiet, Continuous operation • No electricity needed • Low pressure drop • Hollow fiber technology

Parker Finite Air Filters

Compressed Air & Gas Filter - Up to 5000 PSIG - J Series

Finite's inline compressed air and gas J-Series filters feature a robust construction and is specifically engineered for high pressure applications.

Compressed Air Filters - HX Series

Parker Finite's HX Series removes submicronic contaminates from compressed air systems to remove contaimination and avoid damage to equipment and finished goods downstream.

Oil-X Evolution Point-of-Use Oil Vapor and Odor Removal

OIL-X EVOLUTION AC Point of Use Oil Vapor and Odor Removal Compressed Air Filters combine two grades of filtration into one convenient housing.

Oil-X Evolution OVR Oil Vapor Removal Carbon Filter

Oil Vapor Removal filters use an absorbent bed of activated carbon to remove oil vapor from compressed air.

OIL-X EVOLUTION Vacuum Pump Protection Filters

Suction side inlet filters to protect vacuum pumps from harmful contamination in air used by vacuum systems/applications that can cause potential damage to the vacuum pump.

Compressed Air & Gas - Up to 250 PSIG - Top Load Series

Finite's New patented Top Loading compressed air and gas filters are designed to make element replacement faster, even in the most space challenged applications.

Compressed Air & Gas - Up to 185 PSIG - ASME Vessels

Finite's large capacity ASME filter vessels have been designed specifically for our coalescing elements and incorporate large sump capacities and generous exit cavities for maximum performance with low differential pressures.

Compressed Air Filters - Up to 500 PSIG - Finite H Series

Remove oil, water, and particulate contamination from your compressed air with Finite's H-Series Compressed Air Filters.

Compressed Air Filters - JC Series

Remove oil, water, and particulate contamination from your compressed air with Finite's H-Series Compressed Air Filters.

Compressed Air and Gas - Up to 800 PSIG - M-Series

Finite's M-Series compressed air and gas filters with their machined aluminum heads and drawn aluminum bowls are compatible with special gases such as argon, hydrogen, compressed natural gas and helium.

OIL-X EVOLUTION Vacuum Pump Protection Filters

OIL-X EVOLUTION Vacuum Pump Protection Filters are designed for the removal of liquid and solid contamination from the suction side of vacuum pump systems, preventing contamination and potential damage to the vacuum pump.

Compressed Air Filter - JL Series

The Parker Airtek JL Series filter is a severe duty, two-stage combination centrifugal separator and high performance filter. The two-stage design was specifically developed for severe industrial service, central systems and critical applications.

Mist Eliminator - ecomist

New Paragraph

Compressed Air Filter - JL Series

Parker Airtek's Mist Eliminator is designed to optimize oil removal and ensure extremely low pressure drop, protect against catastrophic air/oil separator failure, and is strong enough to withstand the most arduous operating conditions.

OIL-X EVOLUTION Vacuum Pump Protection Filters

Suction side inlet filters to protect vacuum pumps from harmful contamination in air used by vacuum systems/applications that can cause potential damage to the vacuum pump.

OIL-X EVOLUTION Vacuum Pump Protection Filters

OIL-X EVOLUTION Vacuum Pump Protection Filters are designed for the removal of liquid and solid contamination from the suction side of vacuum pump systems, preventing contamination and potential damage to the vacuum pump.

WS Series Water Separators

SWS Series Water Separators High Efficiency Bulk Liquid Removal WS Series Water Separators have been designed for the efficient removal of bulk liquid contamination from compressed air.

Oil-X Evolution Water Separators

OIL-X EVOLUTION WS Water Separators have been designed for the efficient removal of bulk liquid contamination from compressed air.

Great Lakes Air Dryers

GRN- Refrigerated Compressed Air Dryers

The GRN series utilizes ultra-low pressure drop stainless steel heat exchangers to process compressed air flows from 10 to 3000 SCFM. The refrigeration system is controlled by a highly reliable automatic or thermostatic expansion valve in lieu of non-adjusting capillary tube systems that can be responsible for premature refrigeration compressor failures.

- UL Dual Listed Compressed Air Dryer; Canadian & US Specifications

- Fully Hermetic Refrigeration Compressor

- Automatic & Thermostatic Expansion Valves

- Refrigeration High/Low Pressure Shutdown w/HP-Man. Reset (Most Models)

- Fan Cycle Control (Most Models)

- Stainless Steel Refrigeration Gauges

- Refrigeration Suction Accumulators (Most Models)

- Smart Design Timed Solenoid Condensate Drain 50-650 SCFM

- Automatic Zero Loss Float Drains 10-40 SCFM

- Available in Air- or Water-Cooled Models

GNX Cycling Refrigerated Compressed Air Dryers

The GNX series provides extremely energy efficient refrigerated drying capacity of 100 – 2,250 SCFM. The cycling Trans-Temp thermal mass system allows the unit to cycle on and off as changes in system load requires.

- Energy Saving Trans-Temp Thermal Mass Cycling

- Energy Rebate Compliant

- Adjustable Dewpoint

- Fully Hermetic Refrigeration Compressor

- Thermostatic Expansion Valves

- Refrigeration High/Low Pressure Shutdown w/Dual-Man. Reset

- Fan Cycle Control (Most Models)

- Stainless Steel Refrigeration Gauges

- Refrigeration Suction Accumulators (Most Models)

- Smart Design Timed Solenoid Condensate 100-500 SCFM

- Pneumatically Controlled Zero Loss Drains 600-2250 SCFM

- Available in Air- or Water-Cooled Models

EDR High Inlet Temperature Refrigerated Compressed Air Dryers

The EDR Series is designed to accept 23 to 129 SCFM of compressed air at temperatures up to 180°F. The integral ambient pre-cooler and water separator allows the compressed air to be dried to a 39°F Pressure Dewpoint which has a 33% lower moisture content than dryers with 50°F Pressure Dewpoint.

- 39°F Pressure Dewpoint Delivers 33% Less Moisture

- Automatic & Thermostatic Expansion Valves

- Fully Hermetic Refrigeration Compressor

- Stainless Steel Refrigeration Gauges

- Refrigeration Suction Accumulators

- Built in Air-Cooled Aftercooler

- Dual Point Moisture Separation

- Smart Design Timed Solenoid Condensate Drain

- Automatic Zero Loss Float Drains

- Fluid Displacement Zero Loss Drains

- Zero Loss Fluid Displacement Drains

- Zero Loss Displacement Drains

GHRF – High Pressure Refrigerated Compressed Air Dryers

The GHRF series utilizes ultra-low pressure drop stainless steel heat exchangers to process compressed air flows from 75 to 3300 SCFM @ 600 PSIG. The refrigeration system is controlled by a highly reliable automatic or thermostatic expansion valve in lieu of non-adjusting capillary tube systems that can be responsible for premature refrigeration compressor failures.

- 650 PSIG Maximum Inlet Pressure

- Fully Hermetic Refrigeration Compressor

- Automatic & Thermostatic Expansion Valves

- Refrigeration High/Low Pressure Shutdown w/HP-Man. Reset (Most Models)

- Fan Cycle Control (Most Models)

- Stainless Steel Refrigeration Gauges

- Refrigeration Suction Accumulators (Most Models)

- Smart Design Timed Solenoid Condensate Drain

- Available in Air- or Water-Cooled Models

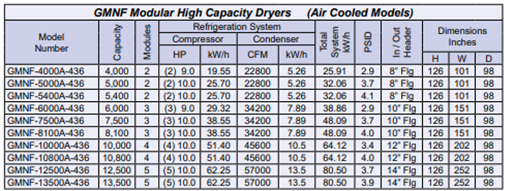

GMNF – High Capacity Refrigerated

The GMNF series is a modular design that utilizes ultra-low pressure drop stainless steel heat exchangers to process compressed air flows from 4,000 – 13,500 SCFM. As a company’s compressed air demand increases, modules can be added to facilitate a streamlined system expansion.

- Fully Hermetic Refrigeration Compressor

- Thermostatic Expansion Valves

- Refrigeration High/Low Pressure Shutdown w/HP-Man. Reset

- Fan Cycle Control

- Stainless Steel Refrigeration Gauges

- Refrigeration Suction Accumulators

- Smart Design Timed Solenoid Condensate Drains

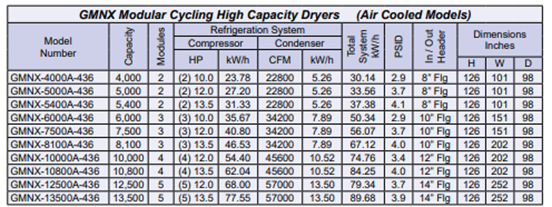

GMNX – High Capacity Cycling Compressed Air Dryers

The GMNX series provides extremely energy efficient refrigerated drying capacity of 4,000 – 13,500 SCFM. The cycling Trans-Temp thermal mass allows each of the modular units to operate independently and cycle on and off as changes in system load requires

- Energy Saving Trans-Temp Thermal Mass Cycling

- Active Redundancy Modular Design

- Fully Hermetic Refrigeration Compressor

- Thermostatic Expansion Valves

- Refrigeration High/Low Pressure Shutdown w/Man. Reset

- Fan Cycle Control (Air Cooled Models)

- Stainless Steel Refrigeration Gauges

- Refrigeration Suction Accumulators

- Pneumatically Controlled Zero Loss Drains

GAC – Refrigerated Compressed Air Chiller

The GAC series utilizes ultra-low pressure drop stainless steel heat exchangers to process compressed air flows from 20 to 825 SCFM @ 100 PSIG to a 40°F discharge temperature.

- Fully Hermetic Refrigeration Compressor

- Automatic & Thermostatic Expansion Valves

- Refrigeration High/Low Pressure Shutdown w/HP-Man. Reset (Most Models)

- Fan Cycle Control (Most Models)

- Stainless Steel Refrigeration Gauges

- Refrigeration Suction Accumulators (Most Models)

- Smart Design Timed Solenoid Condensate Drain

Regenerative Air Dryers

GPS Heatless Regenerative Compressed Air Dryers

The GPS Series is an industrial duty pressure swing adsorption (PSA) regenerative air dryer that delivers a reliable -40° pressure dewpoint with optional designs for -100°. The standard series is optimized for capacities of 25 to 3,000 SCFM

- NEMA 12 Electrical

- Illuminated Power Switch

- US Manufactured Activated Alumina

- Desiccant Fill & Drain Ports

- Adjustable Purge Flow w/Indicator

- Control Air Filter

- ASME Relief Valves

- OSHA Approved Mufflers

- Optional Dewpoint-Demand Energy Management System

GEH External Heated Regenerative Compressed Air Dryers

The GEH Series utilizes a low watt density Incoloy sheath heater to increase operational efficiency and reduce required purge air to 7% or less. The standard series is designed for capacities of 100 to 25,000 SCFM

- NEMA 12 Electrical

- US Manufactured Activated Alumina

- Desiccant Fill & Drain Ports

- Adjustable Purge Flow w/Indicator

- Control Air Filter

- ASME Relief Valves

- OSHA Approved Mufflers

- Insulated Heater & Purge Piping

- Incoloy Sheath Heater

- Heater Over-temp High Limit System

GBS Blower Purge Regenerative Compressed Air Dryers

The GBS Series utilizes an atmospheric blower and low watt density Incoloy sheath heater to increase operational efficiency and eliminate required purge air in the Blower Only Mode. The standard series is designed for capacities of 100 to 25,000 SCFM. The standard Tri-Mode system allows an operator to select a mode of operation at any time.

- Tri-Mode Operating System

- NEMA 12 Electrical

- US Manufactured Activated Alumina

- Desiccant Fill & Drain Ports

- Adjustable Purge Flow w/Indicator

- Control Air Filter

- ASME Relief Valves

- OSHA Approved Mufflers

- Insulated Heater & Purge Piping

- Incoloy Sheath Heater

- Heater Over-temp High Limit System

GMR Heatless Regenerative Compressed Air Dryers

The GMR Series is a pressure swing adsorption (PSA) regenerative air dryer with a full 10 minute NEMA cycle. It delivers a reliable -40° pressure dewpoint and features a compact and efficient design, which includes wall mount capabilities.

- NEMA 12 Electrical

- US Manufactured Activated Alumina Molecular Sieve and activated alumina blend

- OSHA approved mufflers

Compressed Air Filtration

GHN Series air filters remove contaminates from compressed air after compression has taken place.

- Clever & Efficient Housing Design

- Differential Pressure Switch, allowing for remote monitoring of filter performance

- Side Port Condensate Drain

- 300 PSIG Maximum Pressure

- 248°F Maximum Temperature

- Aluminum Housing

GW Series High-Capacity Filtration

GW Series air filters remove contaminates from compressed air after compression has taken place.

- Clever & Efficient Housing Design

- Differential Pressure Switch, allowing for remote monitoring of filter performance

- Side Port Condensate Drain

- 300 PSIG Maximum Pressure

- 248°F Maximum Temperature

- Aluminum Housing

BEKO Technologies Products

RA Non-cycling Refrigerant Dryers

Flow Rate

10 - 480 scfm

Maximum Inlet Air Temperature

130 °F

Maximum Inlet Operating Pressure

10 - 50: 232 psig

75 - 480: 200 psig

Standard Outlet Pressure Dew Point | ISO 8573-1:2010 Air Quality Class

≤ 37-45 °F

Class 4-5

Standard Condensate Drain | Optional

Timer Solenoid

BEKOMAT®

Available Options

3-valve bypass, Cover3More Extended Warranty

Energy Saving Refrigerant Dryers

Flow Rate

20 - 500 scfm

Maximum Inlet Air Temperature

160 °F

Maximum Inlet Operating Pressure

20 - 50: 232 psig

75 - 500: 200 psig

Standard Outlet Pressure Dew Point | ISO 8573-1:2010 Air Quality Class

≤ 37-45 °F

Class 4-5

Standard Condensate Drain

BEKOMAT®

Heatless Desiccant Dryers

Flow Rate

4 - 110 scfm

Standard Outlet PDP | Optional

-40 °F

-100 °F

Maximum Operating Pressure

232 psig (ACC 4-35)

189 psig (ACC 46-110)

Average Purge Air

18%

PN Series high pressure drains for a range of applications with hard coated drain bodies and pressure ratings up to 915 psig:

- 12 CO PN 63 / 13 CO PN 50 / 14 CO PN 25

Full stainless steel bodies with the ability to handle large volume flows and pressure ratings up to 915 psig:

- 3 E 25 / 3 E 63 / 6 E 25

Heated Desiccant Dryers

Flow Rate

4 - 110 scfm

Standard Outlet PDP | Optional

-40 °F

-100 °F

Maximum Operating Pressure

232 psig (ACC 4-35)

189 psig (ACC 46-110)

Average Purge Air

18%

Heated Purge Desiccant Dryers

Flow Rate

100 - 3200 scfm

Standard Outlet PDP | Optional

-40 °F

Maximum Inlet Air Temperature

120 °F

Maximum Operating Pressure

150 psig

Average Purge Air

7%

Membrane Dryers

Flow Rate

1 - 120 scfm

Maximum Inlet Air Temperature

140 °F at 100 psig

120 °F at 100 psig

Fixed or Adjustable Outlet Pressure Dew Point | ISO 8573-1:2010 Air Quality Class

Fixed

Class 2-6

Pre-filter Integrated to Housing

No

Standard Pipe Sizes

¼ - 1 ½”

Available Options

Wall brackets, Cover3More Extended Warranty

Master Pneumatic Products

Dryers/Filters

Many compressed air systems require point-of-use cleaning and drying of the air to supplement a central system. Dryer/filters do this extremely well because of their triple-action cleaning process and their ability to substantially reduce pressure dew points.

Available desiccants for these units include clay, clay with activated carbon, and molecular sieve for as much as 80° dew point suppression. Automatic drains are strongly recommended, although there are a variety options offered — from manual drains to the Warrior electronic drain.

Specifications:

- Size: 1/4" - 1 1/2"

- Ambient/Media Temperature: 40° to 125°F (4° to 52°C).

- Drain: Automatic drain; optional manual or electronic drains.

- Dessicant: Choice of three.

- Fluid Media: Compressed air.

- Inlet Pressure: 150 psig (10 bar) maximum. Consult Master Pneumatic for higher pressure ratings.

- Flow Rate: 7scfm to 300scfm

- 30 scfm (14.3 l/s) for 38-4.

- Mounting: Flanges and front ports for flush

Non-Cycling Refrigerated Dryers and Refrigerated Air Dryers

NON-CYCLING (DRY POWER - MG)700 -5,600 SCFM DryPower

DryPower features a modular design whereby multiple heat exchangers ensure optimum performance throughout its broad capacity range. The highly efficient DRYMODULE exchangers allow lowest dew point levels in all conditions with minimum energy consumptions. This non-cycling refrigerated air dryer's extreme compact packaged design simplifies positioning and maintenance. The sophisticated microprocessor technology and scroll compressors offer the user the most advanced technical solutions.

- Easily removable panels for quick access.

- Extremely compact dimensions (pre-cooler re-heater, evaporator and demister housingin single aluminium module.

- Refrigeration & control circuits in front of unit (separate compartment).

- Multiple heat exchangers in unit rear.

- Oversized demister separator: removes condensate at all air flows.

Scroll Compressor

Precooler-Reheater, Evaporator and Demister

Advanced Microprocessor

Digital display of:

- Dew point (permanent)

- Air inlet temperature (permanent)

- Air outlet temperature

- Multi level menus with multiple password protection allowing extensive programming

- Condensate drain programming

- Volt free general alarm contact

Refrigerated Air Dryers

MTA introduces Hybrid drying technology by combining two drying processes into a single dryer, direct exchange and thermal storage operation; the result is the very lowest energy consumptions.

DE Hybrid: 2 dryers in 1, much more than twice the benefits.

- 20,2000 / SCFM Capacity

- Easy to Use & Maintain

Advanced Microprocessor

- R134A refrigerant offers high overload capacities.

- Easy to use and maintain.

- Operation in high ambient of 115°F, 110°F for DE1600/2000.

- Lowest dew point provided by thermal storage acts as a buffer covering sudden load variations.

- Stainless steel demister removes condensed moisture at all air flows.

- Environmentally safe - no risk of cross contamination between refrigerant and compressed

Nano Air Dryers and Industrial Filters

Air Dryers

Industrial Filters

Nano Air Dryers

R1 cycling refrigeration air dryers

The advanced nano R1 cycling refrigeration air dryer combines the advantages of a direct thermal exchange with thermal storage. It’s two dryers in one. By combining these two powerful energy saving technologies the R1 provides you with the lowest power consumption available in the market today. This cutting edge, patented concept not only reduces your energy bill, it also offers steady dew point performance and reliable operation to ensure you have continuous, worry free, clean and dry compressed air.

With digital controls that automatically manage energy consumption, a unique zero air loss condensate drain that automatically adjusts with demand - the R1 cycling refrigeration dryer saves energy and eliminates seasonal adjustments. It is the ultimate solution to remove moisture from your compressed air system.

Flow Capacity

- 500-4000scfm

Reliability is built in... and backed by our 2 year warranty

Some of the many features and benefits:

- Energy saving design - uses up to 80% less energy than a traditional dryer.

- High ambient dewpoint setting - for additional energy savings in hot ambients.

- Intelligent condensate drain - self calibrating energy saving drain comes standard.

- User freindly digital controls - electronic controls & LED interface on every model.

- Quick & easy start-up - no pre-start up cooling, programming or calibration required.

- Automatic operation - automatically turns itself off and on as needed.

- Built for extreme operating conditions - keeps going through summer and winter.

- No seasonal adjustments - controls and drains self adjust with the seasons.

R2 high temperature cycling dryers

The nano R2 range of refrigerated thermal mass cycling dryers are specifically designed for the unique demands of high temperature compressed air applications. With seven models from 15 to 100 cfm and a 1 micron coalescing inlet filter provided as standard, the nano R2 dryers are the optimum choice for fluctuating air flows and harsh environments.

Perfect for small, non-aftercooled piston compressors or any application with a fluctuating air demand, the R2 Therma-Cycle dryer provides unparalleled reliability, performance and energy savings.

For the optimum in clean compressed air, the R2 dryers can also be supplied with a 0.01 micron after filter, providing comprehensive moisture and particulate removal in a single, cost effective and reliable package.

D1 & D2 modular desiccant dryers

Clean and dry compressed air is easily achieved with the nano ultra-high purity compressed air dryers.

- more for your money - everything needed for installation is in the box

- moisture & particulate protection of your production process

- lower life cycle costs - low energy costs and simplified maintenance

- built in dew point monitoring (optional)

- space saving - models up to 177 scfm can be easily wall mounted

- safe and quiet operation

- flows 3 - 177 scfm at 100 psig operating pressure

- peace of mind - the most reliable product of its kind

D3 modular desiccant dryers

Clean and dry compressed air is easily achieved with the nano D3 ultra-high purity compressed air dryers.

- more for your money - everything needed for installation is included

- moisture & particulate protection of your production process

- lower life cycle costs - low energy costs and simplified maintenance

- built in dew point monitoring (optional)

- safe and quiet operation

- flows 212 - 1110 scfm at 100 psig operating pressure

- peace of mind - the most reliable product of its kind

D4 welded high pressure dryers

The nano D-Series 4 high pressure twin tower desiccant air dryers are designed to remove water vapor from your high pressure compressed air system, lowering the pressure dewpoint to -40 degrees F. No liquid water or ice crystals will form even if the temperature of the compressed air falls to 40 degrees below zero! Designed for the most demanding high pressure applications, the nano D4 twin tower desiccant air dryers are your solution for continuous, uninterrupted clean dry air.

Combining reliable field proven components and a cost effective design with 21st century controls and a digital user interface, there is no better, more dependable, easier to use twin tower dryer available on the market today.

Flow Capacity

- 42-442 @ 1450psig

- 68-824 @ 3625psig

- 88-818 @ 5075psig

D5 heatless twin tower dryers

The nano D-Series 5 heatless twin tower desiccant air dryers are designed to remove water vapor from your compressed air, lowering the pressure dewpoint to -40 or even -100 degrees F. No liquid water or ice crystals will form even if the temperature of the compressed air falls to 40 degrees below zero! Designed for the most demanding applications, the nano D-Series 5 heatless twin tower desiccant air dryers are your solution for continuous and uninterrupted clean dry air.

Flow Capacity

- 200-3000scfm

The advanced design combines reliable field proven components and cost effective operation with 21st century PLC controls and a digital user interface. For clean dry air, there is no better, more dependable, easier to use twin tower dryer available on the market today.

Reliability is built in… and backed by our 5 year warranty on inlet and purge exhaust valves.

D5 externally heated twin tower dryers

The nano D-Series 5 externally heated twin tower desiccant air dryers are designed to remove water vapor from your compressed air lowering the pressure dewpoint to -40 degrees F. No liquid water or ice crystals will form even if the temperature of the compressed air falls to 40 degrees below zero! Designed for the most demanding applications, the nano D5 twin tower desiccant air dryers are your solution for continuous and uninterrupted clean dry air.

Flow Capacity

- 200-3500scfm

The D-Series 5 externally heat reactivated dryers use heat to reduce the use of costly purge air. For consistent performance and cost effective operation these dryers are your optimum choice.

Reliability is built in… and backed by our 5 year warranty on inlet and purge exhaust valves and 10 year heater warranty.

D5 blower purge twin tower dryers

The nano D-Series 5 blower purge twin tower desiccant air dryers are designed to remove water vapor from your compressed air lowering the pressure dewpoint to -40 degrees F. No liquid water or ice crystals will form even if the temperature of the compressed air falls to 40 degrees below zero! Designed for the most demanding applications, the nano D5 twin tower desiccant air dryers are your solution for continuous and uninterrupted clean dry air.

Flow Capacity

- 500-4000scfm

The D-Series 5 blower purge dryers regenerate using a combination of heat and ambient air to minimize - or even eliminate - purge air usage. For consistent performance and cost effective operation these dryers are your optimum choice.

Reliability is built in…and backed by our 5 year warranty on inlet and purge exhaust valves and 10 year heater warranty.

Nano Filters

F1 performance validated filters

Clean and oil-free compressed air is easily achieved with the new range of F1 performance validated compressed air and gas filters.

Nano F1 filters provide:

- improved filtration for your compressor room or point of use application

- reliable and efficient liquid and particulate removal

- space saving design - no tie rod allows easy bowl removal

- five (5) element grades ranging from 25 to 0.01 micron

- nineteen (19) models ranging from 8 to 1500 scfm at 100 psig

- a comprehensive range of accessories

1 year element and a 10 year housing warranty!

F1 centrifugal water separators

The nano F-Series1 range of water separators eliminate 99% of liquids in your compressed air or gas system improving your processes and reducing costly downtime.

An internal shield ensures that the separated liquids cannot re-enter the air or gas stream greatly improving drainage and further improving separation performance.

F1 medical sterile filters

The nano F-Series1 range of medical sterile filters are manufactured from cast aluminum alloy providing enhanced strength and feature an E-Coat™ finish for optimum corrosion protection.

This unique design includes elements with stainless steel end caps for compatibility with autoclave sterilization. Each element is 100% integrity tested and provided with an Air Sterilization Certificate to guarantee the highest downstream air quality.

F1 medical vacuum filters

The nano F-Series1 range of medical vacuum filters are manufactured from cast aluminum alloy providing enhanced strength and feature an E-Coat™ finish for optimum corrosion protection.

Elements are constructed with an oleophobic borosilicate microfiber media with an open cell reticulated foam pre-filter. This unique design provides maximum filtration performance while minimizing pressure drop for optimum energy efficiency.

F1 vacuum pump protection filters

The nano F-Series1 range of vacuum pump protection filters are manufactured from cast aluminum alloy providing enhanced strength and feature an E-Coat™ finish for optimum corrosion protection.

Elements are constructed with an oleophobic borosilicate microfiber media with a custom engineered anti re-entrainment layer. This unique design provides exceptional dirt holding and drainage capabilities while minimizing pressure drop for optimum energy efficiency.

F2 high capacity flanged filters

The nano F-Series2 filters provide:

- Reliable & efficient liquid & particulate removal with low pressure drop

- 1.0 & .01 micron particulate and coalescing filters for dust, oil & aerosol removal

- AC activated carbon adsorption filter for vapor removal performance to .003 ppm

- Nine models in two flow configurations from 1,410 to 10,230 scfm at 100 psig

- ANSI flanged connections ranging from 3” to 10” diameter

- Built in accordance with ASME VIII with a U-Stamp and CRN number*

- Specialized elements for high temperature applications

F3 high temperature dust filters

The nano F-Series3 range of high temperature dust filters are rated for temperatures up to 450 degrees F.

These filters incorporate an innovative push-fit element design with dual o-ring seals to ensure optimum sealing and mechanical strength.

Manufactured in an ISO 9001 approved facility and tested in accordance with ISO 12500.

Inlet/Outlet

- 1/4"NPT - 3"NPT

Flow Rate

- 15-6000scfm

F3 mid pressure aluminum filters

The nano F-Series3 range of mid pressure filters consists of nine models in three different housing designs.

Choose from five different elements including 25, 5, 1 and 0.01 micron coalescing and/or dust filtration, and activated carbon oil vapor removal. The custom engineered filter media is designed to provide low air velocity preventing oil carry over for high efficiency filtration with minimal pressure drop.

Manufactured in an ISO 9001 approved facility and tested in accordance with ISO 8573-1:2010.

Inlet/Outlet

- 1/4"NPT - 2"NPT

Flow Rate

- 94-1885scfm

F4 high pressure stainless steel filters

The nano F-Series4 range of stainless steel high pressure filters consists of 21 models across three pressure ranges offering flow ratings up to 2000 scfm and pressure ratings up to 5000 psig.

Manufactured from high grade 316 stainless steel and corrosive resistant coated carbon steel, the nano F-Series4 are precision engineered with high pressure applications in mind.

Choose from six different levels of contaminant removal including water separation, 25, 5, 1 and 0.01 micron coalescing and/or dust filtration, and activated carbon oil vapor removal.

F5 filter heater combinations

The nano F-Series5 range of heaters and filter heater packages are specially designed for both industrial and breathing air applications providing efficient filtration and precise temperature control between 68 and 248 degrees F.

Using both an open wound heating coil and high accuracy output temperature sensor the F-Series5 reacts quickly to changes in pressure and flow ensuring a consistent temperature across a wide range of operating conditions.

Inlet/Outlet

- 3/8"NPT - 1/2"NPT

Flow Rate

- 27scfm

Aircel Compressed Air Dryer Systems

Dessicant Air Dryers

Refrigerated Air Dryers

Aircel Desiccant Air Dryers

AHLD E-Series Heatless Regenerative Desiccant Air Dryer

The Aircel AHLD E-Series (70-5,000 scfm) is a fully automatic Dual Tower Heatless Regenerative Compressed Air Dryer with an integrated Energy Management Purge Reduction System. The PLC Controller provides complete reliable control of the system with text description of each step in the sequence of operation. The E-Series reliable operation and robust valving, requires no user adjustment and virtually no user maintenance. Our precision engineered components and design deliver outstanding service life and operational durability. Aircel has the experience, engineering and manufacturing capabilities to continuously develop dryers with the highest quality performance.

The Aircel Programmable Controller (APC) and Energy Management System (EMS) is standard on the AHLD. This energy-saving demand cycle reduces purge air and optimizes dryer performance by monitoring the moisture fast and early in the middle portion of the tower desiccant bed. This control panel automatically adjusts the regeneration cycle maintaining dew point and extending the drying cycle. Switching is less frequent, reducing dryer maintenance and fully utilizing desiccant capacity. This addition will improve reliability and performance while sustaining a constant dew point. The end result is an overall purge reduction and significant energy savings.

AEHD Series Externally Heated Regenerative Desiccant Dryer

The Aircel Programmable Controller (APC) and Energy Management System (EMS) is standard on the AHLD. This energy-saving demand cycle reduces purge air and optimizes dryer performance by monitoring the moisture fast and early in the middle portion of the tower desiccant bed. This control panel automatically adjusts the regeneration cycle maintaining dew point and extending the drying cycle. Switching is less frequent, reducing dryer maintenance and fully utilizing desiccant capacity. This addition will improve reliability and performance while sustaining a constant dew point. The end result is an overall purge reduction and significant energy savings.The Aircel AEHD (150 - 3,000 scfm) Externally Heated Desiccant Compresssed Air Dryer is a fully automatic, PLC controlled, selfcontained unit offering a fail-safe design - in the event of power interruption and/or air loss, the purge exhaust valves close preventing damage to the dryer and the process. The combination of 1) high moisture capacity, premium grade, high crush strength activated alumina used in 2) optimally sized ASME code desiccant towers providing low velocity and high contact time through the adsorbent beds delivers long service life and consistent performance.

All Aircel dryers are designed to give our customers the best value available in the industry - reliable performance to CAGI ADF 200 specification while consuming the lowest amoun tof energy possible.

ABP Heated Blower Purge Regenerative Desiccant Dryers

The Aircel ABP (800 - 15,000 scfm) is Aircel’s new blower purge heat reactivated dual tower regenerative air dryer with standard Energy Management System (EMS) for solid peace-of-mind energy savings and consistent operation automatically controlled via an Allen Bradley PLC and a 6” LCD Color Touch Screen.

Why is the ABP Series different?

For added energy savings the ABP Series uses a high efficiency blower to take in ambient air required during the heat regeneration cycle to desorb moisture from the desiccant, no compressed air is used during this phase.

Dry compressed air is used during the dry air cooling regeneration period for reduced heat and dew point spike at tower switchover. This amounts to an average process air use of 2% of the rated capacity of the dryer.

Aircel’s unique parallel cooling mode further reduces the heat and dew point spike prior to tower switchover. During the parallel cooling mode both inlet valves are open for a 10 minute period and divert half-load to each tower further cooling the previously regenerated desiccant bed with a larger volume of air.

HRS-L Zero Purge Heated Regenerative Desiccant Dryers

The Aircel HRS-L (600 - 10,000 scfm) utilize externally heated atmospheric air for regeneration of the desiccant bed. This eliminates the use of compressed purge air for regeneration resulting in an overall reduction in the cost of operation. In the HRS-L the cool-down of the regenerated bed is assisted by a water cooled heat exchanger that further reduces compressed air usage. The result, only a small fraction of process air is consumed during depressurization of the offline tower. This amounts to an average process air use of < .05% of the rated capacity of the dryer.

Ultrapac 2000® Series Heatless Regenerative Desiccant Dryer

The Aircel Ultrapac 2000 Series Dryers (3 - 60 scfm) purification system includes a prefilter, dryer, afterfilter, control system, and automatic condensate drain and silencer. The prefilter retains solids and condensate (oil/water mixture) up to residual oil content 0.03 ppm. The adsorption dryer next in line adsorbs the moisture in the compressed air up to a pressure dew point of -40°F. Finally, in the afterfilter, remaining particles from the drying agent are retained.

Regenerative compressed air dryers use desiccant to adsorb water vapor from the compressed airstream. In the twin tower design one tower dries the air from the compressor while the desiccant in the other tower is being regenerated to provide continuous operation. These dryers are typically referred to as "heatless" or "heated". Heatless dryers do not use any source of heat for regeneration other than the heat given off during the drying phase. This is known as the "Heat of Adsorption". Heated dryers, on the other hand, utilize an external heat source for regeneration and require little or no process air.

Oilfreepac OFP Regenerative Desiccant Adsorbent Air Purifier

The Aircel Oilfreepac Purification System (50 - 5,000 scfm) removes water, oil and dirt particles from your compressed air in one process for clean, oil-free and odor-free air. It is an efficient and reliable heatless compressed air purifier providing an outlet dewpoint of either -40°F or -100°F (Optional). The Oilfreepac system filters oil and adsorbs oil vapor so thoroughly that the residual oil content is below normal detection limits, 1000 times more pure than the normal atmospheric air that we breathe.

Refrigerated Air Dryers

VF Series Non-Cycling Refrigerated Compressed Air Dryer

The Aircel VF Series (10 - 1,200 scfm) offers the highest efficiencies at varying flow conditions in a lightweight, compact design. No other dryer in the industry can offer the efficiency ratings achieved by the VF Series dryers in variable flow operation. VF Series dryers are built with the patented Variable Flow heat exchanger, which allows for desired dew point performance regardless of flow variations. Typically, other dryers with mechanical moisture separators lose performance as compressed airflow velocity increases or decreases substantially around the nominal design point.

The VF Series high efficiency heat exchanger utilizes a three-step process to thoroughly remove condensed moisture from the chilled compressed air. This process provides separation efficiency in excess of 98% throughout the dryer's entire flow range. Our VF non-cycling range is focused on reliable, constant dew point performance in all flow conditions. With its excellent heat transfer coefficients and low-pressure drop, these dryers will outperform the competition in protecting your compressed air system, machinery and tools; and will improve your manufacturing processes.

DHT Series High-Inlet Temperature Refrigerated Air Dryer

The Aircel DHT (20-125 scfm) high inlet temperature refrigerated air dryers are designed for air-cooled reciprocating type air compressors, this compressed air dryer combines an oversized refrigerated circuit, high-efficiency heat exchangers and separator into a single compact unit, with single point air in/out, drain and electrical connections.

These dryers can accept compressed air up to 205°F and provide clean dry air at the outlet. Our high inlet temperature refrigerated dryers have been designed specifically for use with smaller reciprocating air compressors that typically do not incorporate an aftercooler.

RTM Series High-Capacity Cycling Refrigerated Air Dryer

The Aircel RTM Series (2,500 - 30,000 scfm) high-capacity cycling refrigerated compressed air dryers use multiple compressors with defined loading/unloading capacities and a thermal mass storage medium for energy-efficient operation. The refrigeration system cools the thermal mass medium to a predetermined lower temperature. Once that temperature is reached, the system goes into standby mode until the temperature rises to another predetermined set point.

Only then does the system come out of standby mode and once again cools the thermal mass medium. No energy is wasted when demand on the dryer is low. These dryers are ideally suited when large air volumes need to be dried to a reliable and constant dewpoint.

Product Lines

Eliminex Series

Eliminex Mainline Separator

- Removes water & dirt to 3.0 micron

- Available in 1/2" NPT- 6" ASA (150#) Flange

- Available 60-5500 scfm @ 100 PSI

Eliminex Mainline Separator Combo

- Removes water, dirt & oil up to 0.01 micron

- Available in 1/2" NPT - 6" ASA (150#) Flange

- Available 60-3000 scfm @ 100 PSI

Eliminex Series

Eliminizer Mainline Separator

- Removes water and dirt up to 1.0 micron

- Available in 1/4"- 1" sizes

- Available 20-150 scfm @ 100 PSI

Eliminizer Combo Mainline Separator Combo

- Removes water, dirt & oil up 0.01 micron

- Available in 1/4"- 1" sizes

- Available 20-150 scfm @ 100 PSI

Coalescers

Coalescers

- Removes dirt and oil up to 0.01 micron

- Available in 1/4" NPT - 6" ASA (150#) flange sizes

- Available in 60-3000 scfm @ 100 PSI

Oil Extractors

Oil Extractor

- Removes water, dirt & oil vapor up to 1.0 micron

- Available in 1/2" - 1" sizes

- Available in 60-150 scfm @ 100 PSI

Oil Extractor Combo

- Removes water, dirt, oil & oil vapor up to 0.01 micron/0.003 ppm

- Available in 1/2" - 1" sizes

- Available in 60-150 scfm @ 100 PSI

Desiccant Dryer

Eliminator II Desiccant Dryer

- Lowers dew point to -40ºF

- Removes water, dirt and light oil

- Handles up to 30 scfm

- True moisture indicator downstream

- Available in 1/4", 3/8" & 1/2" NPT Port Size

- 1/4" Regulator & Gauge Optional

Desiccant Systems

DRAD Regenerative Desiccant Systems

- Lowers dew point to -40ºF or -100ºF (optional)

- Simple, effecient, with only 2 moving parts

- 4-30 scfm outlet @ 100 PSI available

Refrigerated Dryers & Compressors

Dryers & Compressors

- Energy efficient cycling dryers reduce costs up to 80%; Compact, low maintenance

- Rotary screw & piston compressors available 5-300 HP, long lasting, easy to service

Regulators

Regulators & Heavy Duty Regulators

- Different sizes and styles to meet your needs.

Lubricators

Lubricators & Heavy Duty Lubricators

- Different sizes and styles to meet your needs.

High Pressure Products

Food Grade, 316 Stainless Steel, High Pressure Products

- Meet the needs of the food industry where FDA specs must be followed.

- 316 SS construction available in 60, 90 & 150 scfm

- High pressure units are perfect for natural gas applications

Business Hours

Mon-Fri 8am-5pm

24-Hour Emergency